In this article we will discuss about the history and progress of the cement industry in India.

History of the Cement Industry:

Cement production commenced in India in the year 1904 when a factory was set up at Madras. During 1912-13, three more companies with factories at Porbander, Katni and Lakheri were formed. These, however, commenced production only after the First World War had broken out so that in 1914, only the Madras factory was in operation and total production stood at 945 tons.

The First world war gave a great fillip to the industry. On account of shipping and other difficulties, imports of cement rapidly dwindled while, under the impact of the war, home demand greatly expanded. The govt., herself needed large quantities for war-purposes.

The bulk of the product was purchased by the Munitions Board and the industry worked under Govt., control. In this atmosphere, free from foreign competition but rising domestic demand, the cement output rapidly rose and reached 87000 tons in 1919.

ADVERTISEMENTS:

Immediately after the war, there was a general industrial boom which the cement industry also shared. As the war controls had also been lifted, the industry made large profits and attracted new investors in the field, Several new companies were floated so that by 1924, there were 10 factories with an output of 5.5 lakh tons.

The year 1924, however, saw the infant industry in a state of impending collapse. The industrial boom had burst; demand had declined and internal competition had led to a scramble for markets at any price for delivery over any distance.

The price of cement fell heavily in 1923-24 resulting in losses to share-holders. To internal competition was added competition from abroad, particularly from the U.K. Unable to face the situation, the industry made an application, in 1924, for the grant of protection “as a purely temporary measure”.

There was nothing that the Tariff Board could do in regard to internal competition. As regards foreign competition, the Board proposed a system of conditional bounties to the industry. It also recommended that the existing revenue duty of 15% ad valorem should be substituted by a specific duty of Rs. 9/- per ton on all imported cement.

ADVERTISEMENTS:

The Govt., however, saw no justification for intervention because, in its view, the difficulties of the industry were caused mainly by internal cut-throat competition. The “conditional and hesitating” recommendations of the Board were, therefore, rejected. Directly on the heels of the govt’s announcement, three of the need companies went into liquidation and several others threatened to follow suit.

This state of affairs could not have continued indefinitely. Having been denied govt., help, the manufactures decided to help themselves. The years 1926—29 saw the first step towards cohesion when the survivors of the debacle formed an association known as the cement Manufacturers Association.

The aim of this Association was to fix and regulate prices. The next step was the establishment, in 1930, of the Cement Marketing Company of India to which was handed over the control of the sales and distribution of almost all the manufacturing companies.

The member companies worked on a system of quotas which were based on the stated capacity of each factory. Though the combined potential output was one million tons but the factories did not work for more than 60% capacity.

ADVERTISEMENTS:

It was, however, soon realised that only a complete fusion of manufacture and sales would be necessary to enable the industry to tide over its difficulties. Thus, in 1935, mainly due to the efforts of Late Sir. EE. Dinshaw, the complete merger of the 10 cement companies came into existence.

The aim of the Associated cement companies, on which were also represented the Tata and British interests, was to “make and deliver cement as cheaply as possible so that it may be able to hold its own against any possible internal competition as well as foreign competition and also to secure a complete unison of interests among all those concerned.”

By the end of 1936, the Associated cement possessed an output capacity of 12.65 lakh tons. Although the existence of monopoly forestalled the appearance of competitors, yet new competition arose in the shape of Dalmia cement company in 1937. A battle started between the A.C.C. and the Dalmia cement which lasted several years, both sides suffering heavy losses. But the Dalmia cement was not destroyed.

Since 1930, despite internal and external competition, the progress of the industry was remarkably continuous. Production rose from 5.70 lakh tons in 1930-31 to 18 lakh tons in 1938-39. During the same period, imports declined from 64,000 tons to 21,000 tons.

In 1939, there were 19 cement factories in India employing about 11000 workers. The whole output of the industry was absorbed internally except for a small quantity exported to Ceylon.

The outbreak of the second world war provided yet another opportunity for the industry to expand and progress. On account of shipping difficulties, imports declined to a negligible 5000 tons in 1940-41. The industry, however, could not benefit due to internal dissensions which plagued it.

Moreover, early in the war, the demand for cement had fallen on account of rising cost of house building. Understanding between the rival groups, the A.C.C. and the Dalmia cement, was arrived at by the end of 1940 and early in 1941, the two leading trusts began marketing their product through a syndicate-type organisation, the cement Marketing company of India.

Soon after, with the entry of Japan in the War, large scale construction of aerodromes and many other defence-buildings was undertaken throughout India.

This led to a great increase in the demand for cement on the part of the govt., whose off take of cement amounted to as much as 90% of the total consumption in the country. The stimulus thus given resulted not only in the working of the existing factories to full capacity, but also to the establishment of new factories.

ADVERTISEMENTS:

Large demand, restricted transport facilities, and the almost complete absence of foreign imports pushed up the price-index from 100 in 1939 to 145 in January, 1943. On the black markets, prices were considerably higher. As a consequence, the index of net profits rose from 104 in 1940 to 427 in 1944 (1939 = 100).

A feature of the industry was a considerable concentration of production and capital. In 1944, nine cement plants accounted for 67% of the entire production capacity in the country. The concentration of capital was even greater.

A.C.C. had 13 plants accounting for 66% of the total annual production capacity in the country; Dalmia cement united 5 plants and accounted for 20% of the national production while the remaining 5 companies controlled 5 plants and contributed 14% of the production in the country.

The partition of the country did not affect the industry seriously. Only 10% of the factories with an aggregate of 8% of the workers employed went over to Pakistan.

Progress of the Cement Industry under the Plans:

ADVERTISEMENTS:

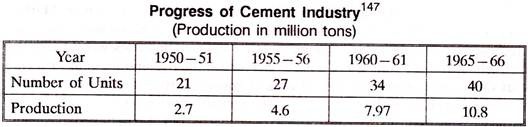

It was under the plans that the industry recorded a most rapid advance. The First plan envisaged the increase of installed capacity to 5.3 million tons through expansion of 11 existing units and the setting up 6 new units. Actual production only reached 4.6 million tons in 1955-56.

However, the demand for cement was so great that the govt., imported about 5 lakh tons at a cost almost 50% above the internal price. At the same time, the distribution and sale of cement in the country was entrusted to the State Trading Corporation of India. It is against this background of demand outrunning supply that the second plan set a target of 15 million tons capacity and 13 million tons production.

This big target implied an enormous expansion in construction projects of all kinds—dams, roads, public undertakings, factory buildings and housing. Unfortunately, this expansion did not come about. In addition, the delay in the implementation of the Steel expansion programmes naturally reacted on the demand for cement since steel and cement arc complementary requirements in construction.

As a consequence, cement development in the Second Plan was modest. Even the revised target of 11 million tons capacity could not be reached. Actual production was about 8 million tons against the target of 13 million tons.

ADVERTISEMENTS:

Discouraged by the performance in the Second Plan, the Planners set a more modest production target of 13 million tons to be achieved by the end of the Third Plan.

However, in view of the paucity of internal resources and the non-availability of cement manufacturing machinery, actual production only reached 10.8 million tons in 1965-66. It was then that the govt., set up the Cement Corporation of India in January, 1965 with a view to establishing units in the public sector.

During the three plans as a whole, the number of factories increased from 21 in 1950—51 to 40 in 1965—66 while production increased from 2.7 million tons to 10.8 million tons, a four fold rise. Total capital invested in 1966 came to Rs.1064 crores and the industry gave employment to 33,741 persons.

Between 1947 — 57, the rate of growth in the industry was very high—the annual average rate being nearly 15%. However, in the subsequent 1957—67 period, it declined to an average of 6.5% per year.

An analysis of regional distribution reveals that the cement industry was well spread all over the country with the exception of Bengal, Assam, J & K, and Maharashtra. Although licences to set up new factories in these states had been given, but the industry’s rate of development was much faster in the South than elsewhere in the country.

ADVERTISEMENTS:

In general, it may be said that the cement industry was in a very advantageous position for expansion. It had plenty of raw-materials; it did not face any foreign competition; its growth was not in conflict with other policy goals and what is more, it had a constantly enlarging market.

In 1966, the per capita consumption of cement in India was only 22 kg. as compared with 715 kg in Switzerland and 305 kg in the U.K. This is bound to rise as more and more mud huts are replaced by cemented houses. The industry in 1966, therefore, was set for a big stride in the future. The only difficulty was with regard to procuring cement manufacturing machinery.