In this article we will discuss about the Technological Progress in a Global Economy:- 1. Meaning of Technology 2. Concept of Technology 3. Determinism versus Choice of Technology 4. Strategies of Technology 5. Sources of Technological Change 6. The Impact of Technological Change 7. Technological Change, Productivity and Economic Growth.

Contents:

- Meaning of Technology

- Concept of Technology

- Determinism versus Choice of Technology

- Strategies of Technology

- Sources of Technological Change

- The Impact of Technological Change

- Technological Change, Productivity and Economic Growth

1. Meaning of Technology:

The term “technology” is of course in common, everyday use and, as with the term “personality”, gives rise to problems of definition. We will look at how different commentators have defined the term.

ADVERTISEMENTS:

As in the words of Takashi Watanabe, technology often takes the blame for social and organizational problems. It is important, therefore, that we are clear about how we use the term. Different commentators have used contrasting and overlapping definitions, and this is confusing.

One dimension concerns breadth. Some use the term narrowly and refer to machinery, equipment or to “apparatus”. Some uses of the term are broad and systemic and refer, for example, to office or manufacturing processes, or to “technique”.

A second dimension concerns the inclusion of human agency. Some definitions of technology refer exclusively to the “hardware”, while others refer to the hardware and organizational arrangements, and thus to the people who make it function in the desired manner.

It is important to note these different uses when comparing research in technological implications, and in interpreting arguments about the social or organizational role of “technology”.

ADVERTISEMENTS:

Thus, one should also be able to:

1. Recognize the problems of defining the term “technology”.

2. Analyse and compare different definitions of the concept of technology.

3. Recognize different levels of mechanization.

ADVERTISEMENTS:

4. Recognize “determinist” arguments about technology.

2. Concept of Technology:

During the 1980s, applications of computing and information technology spread into just about every area of our working lives and too many aspects of our social and leisure activities too. Computerized systems today contribute to the design, production and test of many manufactured goods.

Offices in all sectors are now typically equipped with word processing, computerized information systems, electronic mail, facsimile transmission, and other communications tools such as local and wide area networks. We get cash from a computer terminal outside the bank.

Our hotel reservation is stored on the computer which calculates our bill when we check out, including telephone calls which are logged by computer. In some larger restaurants, when we order a meal, the waiter keys the order into a computer terminal and a printout of the order appears in the kitchen for the chef.

In short, most organizations are today computer-dependent. Large organizations, in particular, now typically spend considerable sums of money on backup arrangements to cope with system failures, and “disaster recovery” has become a major new consulting business, helping organizations deal with major catastrophes such as fire and flood which can threaten to wipe out the business as well as its computer system.

This is a picture of slow evolution, not radical revolution. Unmanned factories and paperless offices are not as common in practice as predictions of their arrival.

Tom Forester (1989) argues that most of the evidence now shows new technology creating jobs rather than creating redundancy, and improving quality of working life instead of de-skilling. How did those myths about the “information technology revolution” arise? Friedman and Cornford describe the tendency of the computing profession to “advance the clock”.

It is important to appreciate that technology has to be studied as something that changes. It is not static. It is also useful to remember that technology is pervasive. Those aspects of our surroundings that are most familiar to us are often the most difficult to consider objectively.

ADVERTISEMENTS:

If we were to examine the effect that technology has on anything at all, then we must be clear what we mean by the term. The term “technology” is now used with such a wide variety of meanings that it has become ambiguous. We must therefore begin by exploring that variety and ambiguity.

Sociologists, and others, have “discovered” that technological developments are major sources of social, economic and political change, for both good and evil. Alvin Toffler, for example, refers to “that great, growling engine of change—technology”. It has become fashionable to study and to make pronouncements on “technological implications”.

This concern began to replace the human relations school in the study of organizational behaviour in the 1950s. The promises, and threats, of the microprocessor revolution revived this concern in the 1980s. And -despite the fact that computers have been around since the 1940s, the term “new technology” is still in common contemporary use.

Langdon Winner, an American commentator on modern technology, has pointed out that the term has widened in meaning as concern for technology implications has grown. It has been transformed from a precise, limited and rather unimportant term “to become a vague, expensive and highly significant one.

ADVERTISEMENTS:

But today, it is widely used in ordinary and academic speech to talk about an unbelievably diverse collection or phenomena—tools, instruments, machines, organizations, methods, techniques, systems, and the totality of all these and similar things in our experience.

How has this confusion arisen? Rapid technical developments leave the language behind. The word “technology” is a convenient umbrella term that enables those of us with a poor technical understanding to talk about such important phenomena.

So this ambiguity in the use of the term paradoxically reflects its pervasive and profound influence on modern society and our realization that we need to discuss and understand it.

We can also argue that this convenient way of using this language leads us to oversimplify and polarize technological issues. It is either a good thing or it is bad; you are either for it or against it.

ADVERTISEMENTS:

We need a more precise definition in order to study technology and its implications from a social scientific point of view. Group psychotherapy, pocket calculators and space shuttles do not appear to have much in common. But they have all been described as “technology” at some time.

The word that, “has come to mean everything and anything threatens to mean nothing.” Winner identified three broad but distinct uses of the term “technology”— apparatus, technique and organisation.

Apparatus:

This simply means physical, technical devices such as tools, instruments, machines, appliances, gadgets and weapons that are used to accomplish a variety of tasks. This is probably the most common and is certainly the most simple conception of technology.

Technique:

This refers to technical activities such as skills, methods, procedures or routines with which people perform to achieve particular purposes. The Greek word technique means art, craft or skill. Apparatus is not purposive. Techniques are related to specific human goals.

Organization:

Winner reserves this term for social arrangements such as factories, bureaucracies, armies, research and development teams and so on, that are created to achieve technical, rational and productive ends.

So when someone uses the term “technology”, they could be speaking either about a physical device, a human skill, a social arrangement, or some combination, or all of these. This confusion can be seen in the work of those who have studied the implications of technology for organizational behaviour.

ADVERTISEMENTS:

We are concerned here with technology applied to production and administrative processes. This is different from the application of technology in new products. Many researchers in the field of technological change have used this distinction between process and product innovation. Here we are concerned with the former.

Here are three definitions of technology that have been used by well known and influential organizational behaviour researchers. Consider each definition and identify what, if anything, is being confused using Winner’s distinctions as a guide.

1. Technology is the actions that an individual performs on an object, with or without the assistance of mechanical devices, in order to make some change in that object.

2. The specific technology of the organization is, then, the collection of plant, machines, tools, and recipes available at a given time for the execution of the production task and the rationale underlying their utilization.

3. Technology is the application of science to invent technique and its supportive artifacts (machines) to accomplish transformations of objects (materials, information, people) in support of specific objectives.

There are two additional definitions:

ADVERTISEMENTS:

Material technology: “The technology that can be seen, touched and heard”; and Social technology “which seeks to order the behaviour and relationship of people in systematic, purposive ways trough an elaborate structure of co-ordination, control, motivation, and reward systems.”

Material technology is what Winner calls apparatus. Social technology is Winner’s organisation and includes job definitions, payment systems, authority relationships, communications channels, control systems, disciplinary codes, “all of the many other rules and decision-making procedures which seek to govern what work is done, how it is done, and the relationships that prevail between those doing it”.

3. Determinism versus Choice of Technology:

Different technologies make different demands on those who work with them. It is clear that the technology of an organisation determines, at least to some extent, the nature of work in that organization.

If we compare a hospital with a biscuit-making factory, a consultancy firm with a coal mine, it seems reasonable to argue that the technology of these organization determines:

1. The kinds of tasks that have to be done.

ADVERTISEMENTS:

2. Job design, or the horizontal division of labour.

3. The organization of work or the grouping of jobs.

4. The hierarchy through which work is planned and coordinated, or the vertical division of labour, or organization structure.

5. The knowledge and skills required to carry out the work.

6. The values and attitudes and behaviour of workers.

The argument that technology can be used to explain the nature of jobs, work groupings, hierarchy, skills, values and attitudes in organizations, is called technological determinism. The determinist assumption that work has to be organized to meet the requirements is widespread.

ADVERTISEMENTS:

Technical innovation has three main phases. The first phase is invention someone has a creative idea. The second phase is exploitation practical applications are developed. The third phase is diffusion more people see the advantages of the new idea and apply it. This third phase then triggers more creative ideas.

Technical change thus encourages more technical change. Andrew Friedman and Dominic Corn- ford (1989) argue that computing technology is auto-generative, a term they use to describe how innovations derive from the users of computer systems as well as from their original designers.

The process of technology development is intrinsically self-stimulating and self-perpetuating. From this perspective, technology does appear to be out of our control and organisation structures appear to be locked in to its demands.

The logic of technical development appears to block choices as to the direction of those developments and their applications. Organizations may simply be forced to use new technologies as a result of competitive pressures.

Continuous innovation is also a way of life in the capitalist industrialized world, both in the development of new products and services and in new production processes. Technical innovation is central to maintain “competitive advantage” in international trade.

There is, therefore, an economic determinism behind technical innovation. Companies that do not introduce the improved technologies that their competitors use must inevitably fail when their customers desert them.

There is now evidence to show that the technological determinist argument is over simplified. In Toffler’s view, technology suggests ways in which it may be used. That is different from the claim that it determines what happens. There are three broad areas of choice in the process of technical change which weaken the technological determinism argument.

First, there are choices in the design of equipment, tools and machines—apparatus. The main choice appears to be the extent to which the control of operations is built into the machine, or left to human intervention and discretion.

There are cases of automated controls being taken out of aircraft cockpits, ship bridges, and railway engine cabs when it was discovered that pilots and drivers lost touch with the reality of their task, surrounded by sophisticated automatic controls which functioned without their help. The task in each case had been automated to the extent that when human intervention really was required, mistakes were made.

Second, there are choices in the goals that technologies are used to achieve. Competitive pressure is just one reason for using a particular technology. Organisations also innovate to reduce costs and solve production bottlenecks and other problems. These reasons may reflect the demands of internal accounting procedures as well as the desire to improve price and delivery for the customer.

Managers also promote technical innovation for personal and political reasons, to give them more power over resources and influence over decisions, more status and prestige in the competition for promotion, and tighter control over their subordinates.

Third, there are choices in the way in which work is organized around technology. Demands made on human skill and knowledge depends partly on the technology and partly on the design of jobs. Job design depends on management decisions as well as on the type of machinery in use.

The redesign of car assembly work by the Swedish company Volvo shows how even this type of work is not dictated by the machinery of production. There are thus choices about the ways in which given technologies can be used by an organization.

These are called “strategic choices” because they depend on management decisions about the strategy behind the development and application of specific pieces of apparatus. Managers have discretion about the design of technology and about the organization of jobs around technology.

The use of that discretion depends more on the assumptions that managers make about human capabilities and constraints than on the technical capabilities of specific pieces of apparatus. These are called “psychological assumptions” because they concern managers’ beliefs about the behaviour of individuals and groups of people at work.

To consider the impact of a particular technology is to consider the wrong questions, or at best to consider only a part of the issue.

Both technology and its effects are the result of a series of management decisions about the purpose of the organisation and the way in which people should be organized to fulfil that purpose. This implies that we should not be studying technology at all, but that we should instead be analysing managers’ beliefs, assumptions and decision-making processes.

The argument regarding technical change viz-a-viz decision making process have five related components:

1. What: The characteristics of the technology.

2. Why: The goals pursued by management.

3. How: The organisation of work around the technology.

4. Consequences: Human, organizational, financial.

5. Feedback: The effects of past changes on future decisions.

In this perspective, technical change acts as a trigger to the processes of management decision-making. The choices that form in those processes, concerning why and how the technology is to be used, determine the outcomes of technical change.

Technology, thus, has limited impact on people or performance in an organization, independent of the purposes of those who would use it and the responses of those who have to work with it. The technological determinism case is, therefore, weak: the strategic choices are crucial.

4. Strategies of Technology:

Competition is essential both to the innovation process and to capitalist economic development. But so, is co-operation. The perennial challenge to policy-makers and to managers alike is to find the right balance of competition and co-operation which can take place.

Today this problem has taken on a new importance, for several reasons. One is that the manner in which technological innovation is organized is changing worldwide. These changes, which will only intensify under liberalized trading regimes, relate not only to the way in which research is organized but also to the way in which new technology is acquired and commercialized.

Accordingly, corporate technology strategies are no longer simply matters of setting R&D budgets and identifying projects on which to lay bets. With an interdependent global economy, technology strategy must attend to both technology acquisition and commercialization issues.

While there is usually some consideration given to the impact of monopoly and competition on incentives to innovate, it is always implicitly assumed that the price mechanism can effect whatever coordination the economic system requires.

Typically there is no discussion how inter-firm agreements, vertical, lateral and horizontal, can positively impact the process. It is not surprising, therefore, that the economics textbooks do not convey a sense that corporate technology-acquisition strategies or inter- firm co-operation are desirable, or even subjects worthy of study.

Paul Samuelson has always acknowledged the importance of technological change in his leading text, but then, like many others, he proceeds to ignore it. While it is the dynamic properties of capitalism that constitute the basis of our confidence in its superiority to other forms of economic organization, the theory is based on a model that assumes an unchanging technology.

When technology is taken into account, the economics profession at large has treated it as events transpiring inside a black box, and has “adhered rather strictly to a self-imposed ordinance not to inquire too seriously into what transpires inside that box.”

Therefore, it is not surprising that economists have not had much to say about corporate technology strategies and the role of cooperation. Policy analysts and policy-makers have instead both stressed the value of pluralism and rivalry as the best organizational arrangement to promote innovation.

Co-operation will become increasingly necessary to promote competition, particularly when industries are fragmented and market barriers are low. Very few firms can successfully “go it alone” any more.

The sources of know-how are dispersed globally, and the capabilities needed to commercialize new technology are rarely found inside a single firm or a single country. Thus global co-operation along firms has become increasingly relevant to national economic development and growth.

Co-operation in turn requires inter-firm agreements and alliances, as well as a well-functioning price system. In this regard, the Japanese form of industrial organization, with complex inter-firm relationships, may have distinct advantages. European and US firms are now only beginning to learn how to co-operate effectively in order to compete.

One consequence of this adaptation to the enlarged scope of the market will be that managers must become more adept at managing inter-firm relationships. Indeed, the very concept of the corporation may well have to be reconsidered when enterprise performance is intimately linked to the performance of one’s co-ventures.

Similarly, at the level of public policy, technology and competition policy must be crafted so as to be sensitive to the needs of innovating firms.

In some countries this is likely to require greater inter-agency co-ordination. In the USA this will need to be coupled with judicial and legislative changes that recognize that some co-operation, even among competitors, is generally beneficial when it serves the requirements of innovation.

The concept that is necessary for technological development must become embedded in a firm’s global technology strategy, if it is to compete successfully in a world where the sources of know-how are globally diffused, where imitation is often easy and where governmental barriers to trade and investment are evaporating.

The following section explores how inter-firm (co-operative) agreements to access technology and complementary assets can be made an integral part of a firm’s technology strategy.

Sourcing Strategies:

There are a number of modes by which technology lying external to the firm can be acquired. It may be easy to copy, if it lacks intellectual property protection, and can be reverse engineered at low cost, as with some microprocessors.

Thus imitation is often a viable acquisition strategy. When the technology is legally protected, it is hard to copy and the innovator is willing to sell. They include licensing, contract R & D, R & D Joint Ventures and bilateral collaborative arrangements.

Licensing is the most familiar of these approaches. A firm possessing valuable know-how that is protected can contract to let others use the technology in question.

A license agreement will often be accompanied by a know-how agreement under which the owner of the intellectual property in question will contract to assist the buyer in developing a comprehensive understanding of the technology in question. Contract R & D is also an important mode, though it is also fraught with hazards.

When a buyer commissions R&D work to be performed under contract, it is usually in recognition of the fact that the provider of the R&D services is better positioned to generate a desirable output from R&D than is the buyer itself.

Unless the technology to be developed can be specified with great precision, and the costs of the requisite development activities can be gauged with considerable accuracy, contracting to develop technology using fixed-price contracts is not easy, as it is difficult to specify and cost-out the object of the development activity at issue.

Modest technological endeavour can be arranged this way more satisfactorily than ambitious ones but are exposed to obvious incentive hazards.

R&D joint ventures make sense as external procurement mechanisms when the other party can bring certain capabilities to the venture that the collaborating party does not possess. Other properties of joint ventures are that they reduce risk when project costs are high; and in the R&D area, they may reduce duplication without necessarily reducing variety.

An inherent flaw of capitalist market economics is that they often cause patent races and other forms of socially wasteful R&D duplication. There may not be a better system for promoting innovation than capitalism, and gross inefficiencies associated with duplication can be reduced by joint ventures.

Another collaborative mechanism involves bilateral exchanges of know-how and other assets, as with cross-licensing, patent-pooling and, more recently, technology transfers, in return for some other non-pecuniary commercial favour, such as access to distribution facilities.

These services are often difficult to obtain otherwise, particularly under simple purchase contracts; and the reciprocal nature of collaboration can bring a degree of incentive capability to the arrangement that would not otherwise be available.

5. Sources of Technological Change:

When we think of technological innovation, we often distinguish between product innovation (new product introductions) and process innovation. While conceptually distinct, the two are often related.

In the early portion of a product’s life, product design is critical. A product’s early users are almost always more interested in product performance than in price. Considerable product redesign is undertaken to make the product even more useful and desirable for its users. Abernathy has referred to this early phase of product technology as the search for the “dominant design”.

Dominant designs are those products that make a market such as Ford’s Model T car, the DC-3 airplane, the Xerox 914 copier, Kodak’s “brownie” camera and the IBM PC. In this early going, the production process is most apt to be a job shop or a near-job shop.

As acceptance of the dominant design proceeds, however, cost reduction becomes increasingly important. Process innovation— geared primarily to lowering costs, increasing yield, and gaining production speed—commands management attention. Changes become less and less radical as the product, the process, and the organization become more and more standardized.

Product Innovation: Assessing the Technological Fortunes:

Spotting the product designs that will be commercially successful is an uncertain business at best. It has been suggested that a new “technological winner” must score high on a mix of separate criteria.

To the extent that a product’s inventive merit is strong, its marketing features attractive, and any required engineering and operational changes either slight or fully anticipated, a new product is likely to be a commercial success. A failure in any of these dimensions can spoil an otherwise promising prod.

Pinpointing a promising technological advance is unavoidably subjective. A number of these approaches to forecasting the success of a new product use the Delphi method, combining an expert panel with probability measures.

Each panel expert is asked to indicate his or her own view of an R & D project’s success. These opinions are collected, tabulated, and usually reviewed again by the expert panel, which can then revise its initial probability selections. Such assessments can be made at regular intervals over the years.

Process Innovation:

The sources of process innovation are similarly, perplexing. Some innovations stem from a company’s own work, some stem from advances made by equipment or materials suppliers, and some result from copying or acquiring the technology developed by others.

Although the sources of process innovation are often baffling, the character of process innovation is less so. Moreover, an understanding of the character of process innovation carries with it some important lessons about how productivity can be enhanced.

A useful touchstone for a discussion of the nature of process innovation is the empirical phenomenon typically referred to as the “learning curve.”

The notion underlying the learning curve derives from the actual experiences of manufacturers in some diverse industries. The universality of the learning curve has been demonstrated in a variety of industries, and most notably in the electronics industry.

For the mathematically inclined, the learning curve relationship can be expressed as:

y = ax-b

where X is the cumulative volume of units produced from the first unit, and Y is the cost of producing the X th unit. The coefficient ‘a’ represents the cost of the first unit and the exponent ‘b’ indicates the sensitivity of unit cost to cumulative volume.

Composition of the learning curve:

So much for the mathematics. What does the learning curve really represent and how can it be of use? Many factors stand behind the learning curve, and all of them can systematically reduce costs over the life cycle of the product.

These factors can be grouped into major categories: Workforce- related factors are mere short-run in character, and for some, distinguished the learning curve from the broader notion of the “experience curve.”

The experience curve is also a relationship between cost and accumulated volume, but it is generally associated with longer term factors dealing with process and product modifications as well as factors related to the workforce. Nevertheless, the terms “learning curve” and “experience curve” are often used interchangeably.

6. The Impact of Technological Change:

Technological change may involve new products, improvements or cost reductions for existing products, or better ways of managing the operations of a business. In some cases, the changes may seem simple and the results rather trivial, such as coating paper clips with colored plastic to prevent them from leaving marks on a page or tapering one side of the buttons on a shirt to make them easier to fasten.

In other cases, the technological advances may be brilliant and the impact on society highly significant. Consider the development and evolution of the electron microscope. The best optical microscopes can focus on objects as small as 1000 angstroms in width. During the 1930s, scientists learned to focus streams of electrons in the same way that optical devices focus light.

The first electron microscopes achieved resolution of about 100 angstroms— ten times better than the optical microscopes. During the next sixty years, research efforts significantly improved the instruments. Today, commercially available electron microscopes can focus on objects as small as one angstrom—a thousand times better than the best optical devices.

This capability has allowed biologists, chemists, and physicists to make important discoveries. For example, it has enabled medical researchers to examine and manipulate bacteria, viruses, and genetic structures as they search for cures for diseases.

7. Technological Change, Productivity and Economic Growth:

Economists use several measures to assess the performance of the economy. One of the most important is productivity, defined as the ratio of output to one or more inputs. Productivity is a key concept because it determines the standard of living that a country can achieve.

In any given year, the total value of income received by individuals is based on the total value of goods and services produced. Thus, the only way for all consumers to have more real income is for the productivity of the inputs, used to produce those goods and services, to increase.

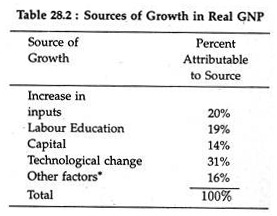

The most common productivity measures is labour productivity—output divided by the quantity of labour. If labour productivity can be increased, workers may be able to earn higher wages. Labour productivity has increased over time. However, there have been significant differences between countries.

Percentage changes in labour productivity between 1970 and 1989 are provided in Table 28.1 for selected countries. Note that the rate of increase for the United States is less than every nation except Canada and Sweden. Slow growth in labour productivity has been a major concern in the United States in recent years.

Productivity increases as workers accumulate more human capital and as the capital stock of the economy increases. Changes in relative input prices can also affect the measured rate of labour productivity.

For example, if capital becomes relatively more expensive, firms will use more labour and less capital. Thus, the ratio of output to labour input will decrease. Conversely, higher wage rates tend to reduce labour usage and to increase the measured rate of labour productivity.

The output-labour ratio is commonly used to measure productivity because it is easy to quantify. However, a better indicator is total factor productivity, which compares changes in output with changes in both labour and capital inputs. Using this approach, it is possible to identify the sources of economic growth over time.

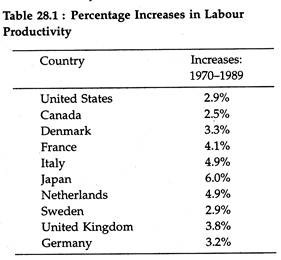

A study by Denison focused on economic growth as measured by the change in real income in the United States between 1929 and 1982. The average annual growth rate in real income over the period was 2.8 percent. The estimated components of growth are shown in Table 28.2.

[* Economics of scale, improved worker-safety and health conditions, pollution abatement, and fewer labour disputes.]

Note that the single-most important source of economic growth between 1929 and 1982 was technological change. Almost one-third of the increase is attributable to improvements in technology.

It is also important to observe that about 20 percent of growth was due to higher education levels of workers. Clearly, knowledge, whether associated with new or improved products or embodied in workers, is crucial to economic progress.

Industrial Innovation:

The famous Harvard economist distinguished among invention, innovation, and diffusion. Invention can be thought of as the creation of new ideas. Innovation represents taking those ideas and transforming them into something that is useful for society. Diffusion is the process whereby the new product or process becomes available throughout the society.

In many cases, inventions never get to the innovation stage. In other cases, innovations fail to become widely adopted. Sometimes the problem is that an invention or innovation provides no real technical advantage or is not economically viable. But there are also instances when truly beneficial ideas languish for many years.

In the early days of sailing, scurvy was the worst killer of sailors. In 1601, an English sea captain found that two or three teaspoons of lemon juice a day provided almost complete protection against the disease. His finding was quite well known at the time, but it was not until 1865, over two hundred and fifty years later, that the remedy was widely used and scurvy ceased to be a threat among British sailors.

Product versus Process Innovation:

Innovation can be divided into two broad categories. Product innovation involves the bringing of new goods or services to the market, while process innovation is concerned with new techniques that reduce costs of producing and distributing existing products.

For a successful product innovation, the good or service will generate a stream of economic profit. In the early years, the firm may lose money as it attempts to launch the product and gain consumer acceptance. Later, there may be a period of rapid growth as the good or service becomes widely used and competitors provide substitutes.

After the product has been available for a number of years, sales may stagnate or even decline.

In evaluating a product innovation, the firm can use the techniques of capital budgeting. An innovation usually involves a substantial initial cost and a stream of future profits. Basically, the question is whether the present value of profits is likely to exceed the upfront cost of bringing the product to the market.

Evaluation of process innovation is similar. The initial cost of implementing the innovation must be balanced against the future cost-savings that will result from the improved process. If the net present value is positive, then the new technique should be incorporated into the production process.

To illustrate the firm’s decision, consider the example of a new process that could reduce the fuel cost of producing electricity. Suppose that an electric utility has generators that have been in service for many years. At present, there is no capital cost— the total cost of generation is the cost of fuel plus the firm’s operation and maintenance expense.

If the, new generation technology is adopted, the firm could reduce its operating costs but would have to pay the initial capital cost. For the process innovation to be profitable, the operating cost-savings would have to be greater than the initial cost.

Successful Innovation: The Gillette Sensor Razor:

Gillette’s Sensor razor is an example of successful product and process innovation. In the mid 1980s, engineers at Gillette perfected the design of a new hand razor with flexible twin blades that adjusted to the contours of the shaver’s face. The new design provided a closer and smoother shave than any razor on the market.

When it was introduced in 1990, the Sensor was a near instant success. In the first two years, the company sold 50 million razors and more than two billion of the twin-blade cartridges. Today, the product is by far the top-selling razor in the United States, with over 40 per cent of the market for non-disposable razors—nearly triple that of its nearest competitor.

The design of the new product was the easy part of the Sensor project. The challenging problem was finding technology that would allow the firm to profitably manufacture millions of razors and blade cartridges each year. With that volume, a reduction of even a tenth of a cent per unit cost could mean a large increase in profits.